The Role of Aluminium Die Castings in Renewable Energy Equipments

The Role of Aluminium Die Casting in Renewable Energy Equipment

Meta Description:

Discover how aluminium die casting enables high-performance renewable energy equipment from solar inverters and wind turbines to EV charging stations and battery storage systems.

Introduction

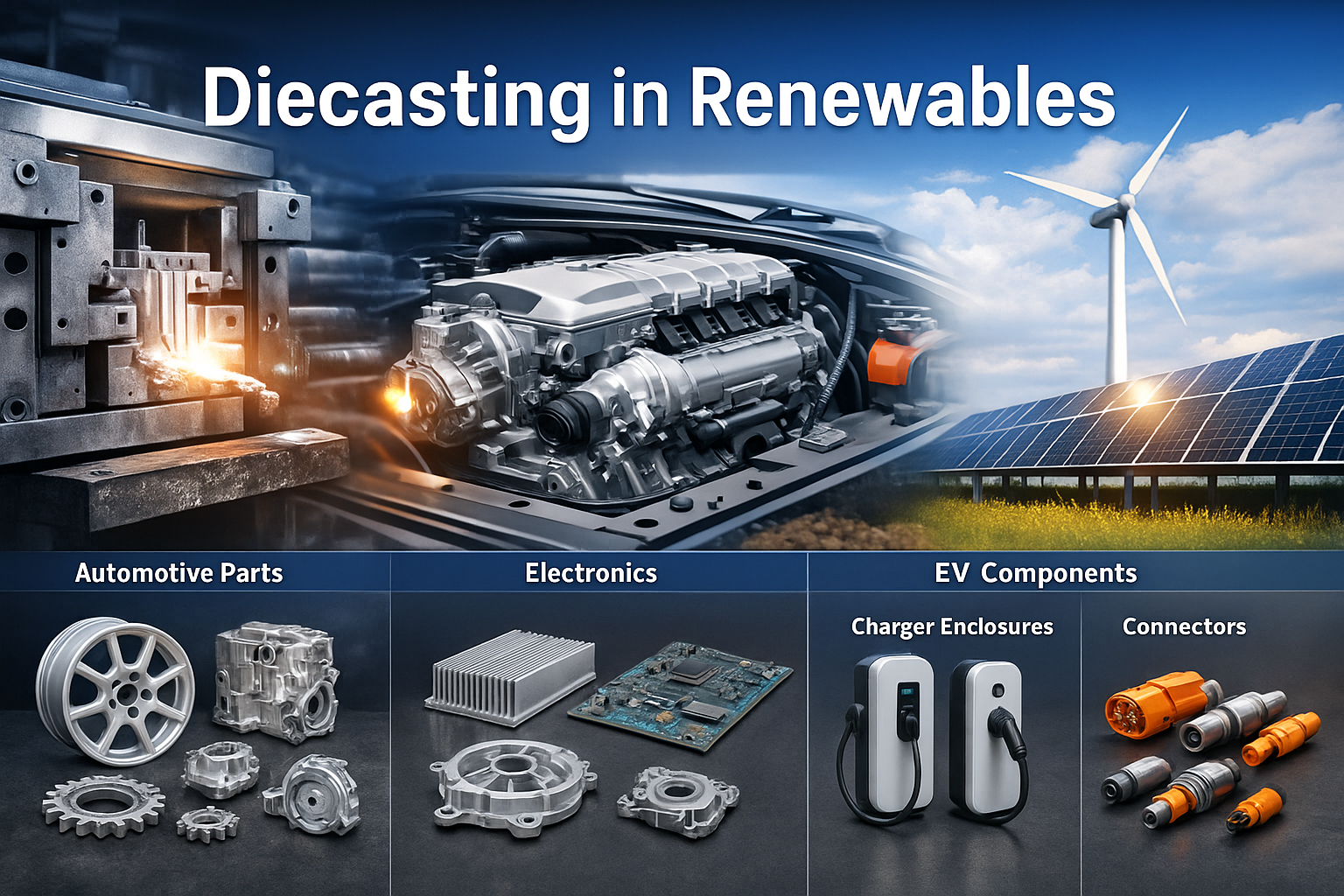

The global shift toward clean energy has accelerated the demand for components that are durable, lightweight, thermally efficient, corrosion-resistant, and cost-effective. As solar, wind, and EV infrastructure scales rapidly, manufacturers are turning to aluminium die casting to meet the strict performance requirements of outdoor renewable-energy systems.

Aluminium has become a preferred engineering material across the renewable industry thanks to its superior strength-to-weight ratio, excellent corrosion resistance, and outstanding thermal conductivity all essential for modern power-electronics and energy-generation equipment.

Why Aluminium Die Casting Powers Renewable Energy Systems

1. Lightweight and High Strength

Renewable equipment often needs to balance rigidity and weight reduction especially in wind, solar, and EV charging systems. Die-cast aluminium delivers the required structural strength without heavy steel fabrication.

2. Exceptional Corrosion Resistance

Outdoor equipment is continuously exposed to rain, dust, humidity, and UV radiation. Aluminium’s natural oxide layer offers long-term protection, making it ideal for:

- Solar inverter housings

- EV charger enclosures

- Wind turbine components

- Battery storage systems

3. Thermal Efficiency

Power electronics used in renewable energy such as inverters, rectifiers, and controllers generate significant heat. Aluminium die castings act as natural heat sinks, improving cooling efficiency and extending equipment lifespan.

4. Eco-Friendly and Fully Recyclable

With its 100% recyclability and minimal lifecycle emissions, aluminium aligns with global sustainability goals and the renewable-energy mission.

Applications of Aluminium Die Casting in the Solar Industry

1. Solar Inverter Housings

Solar inverters are among the most thermally sensitive parts of a PV system. Aluminium die castings are used for:

- Rugged outdoor housings

- Heat-dissipation structures / integrated heat sinks

- EMI / RFI shielding

- Connector and terminal blocks

Optimized aluminium housings improve thermal reliability, waterproofing (IP65/IP67), and long-term durability.

2. Mounting Structures & Support Components

Lightweight aluminium brackets, clamps, and connectors reduce installation time and resist corrosion especially in coastal or high-salinity regions.

Applications in the Wind Energy Sector

1. Generator Housings

Wind turbine generators require robust, vibration-resistant components. Aluminium die castings provide high strength while reducing overall nacelle weight.

2. Nacelle Components

Key aluminium die-cast parts include:

- Bearing housings

- Cooling system parts

- Covers and protective shields

These enhance efficiency while maintaining structural integrity under heavy mechanical loads.

3. Brake & Control System Components

Die-cast aluminium supports high-precision components used in turbine braking and pitch-control systems.

Applications in EV Charging Infrastructure

1. EV Charger Body Enclosures

Aluminium die castings are preferred for AC and DC fast chargers due to their:

- High impact resistance

- Corrosion protection

- Heat dissipation for high-power electronics

- Sleek, durable exterior design options

2. Thermal Management Components

High-power DC fast chargers need efficient cooling. Aluminium castings serve as:

- Heat exchangers

- Cooling plates

- Housing-integrated heat sinks

3. High-Precision Electrical Connectors

Die-cast aluminium ensures tight tolerances for sockets, connectors, busbars, and support structures.

Applications in Battery Energy Storage Systems (BESS)

1. Heat Sink Enclosures

Battery modules require efficient thermal pathways to prevent overheating. Aluminium die-cast parts are ideal for:

- Battery module housings

- Cooling channels

- Thermal plates

2. Structural Frames & Support Parts

Aluminium components keep BESS systems lightweight yet structurally strong making transportation and installation easier.

3. Connector & Terminal Housings

Die casting provides precision and safety in high-current connections.

Why OEMs Prefer Aluminium Die Casting for Renewable Applications

1. Cost-Effective Manufacturing

Once the tooling is created, die casting enables rapid production of complex parts at a low per-unit cost ideal for large-volume solar, EV, and wind industries.

2. Design Freedom

Manufacturers can integrate ribs, heat sinks, mounting points, channels, and even embedded electronics into a single casting, reducing assembly time and improving reliability.

3. High Production Scalability

Die casting supports mass manufacturing requirements of fast-growing renewable-energy sectors.

4. Superior Reliability for Harsh Environments

Outdoor-clean energy systems operate for 10–25 years. Aluminium castings deliver the longevity required for high-reliability performance.

Sustainability Impact

- Aluminium is 100% recyclable with no loss in material quality

- Recycling aluminium saves up to 95% energy compared to primary production

- Lower lifecycle emissions support ESG goals

- Aluminium promotes a circular economy for renewable energy equipment

These factors make aluminium die casting a vital contributor to the global clean-energy transition.

Conclusion

As solar, wind, EV charging, and energy-storage systems continue to scale globally, aluminium die casting has become the backbone of modern renewable energy hardware. Its combination of lightweight strength, corrosion resistance, thermal performance, and recyclability makes it the preferred choice for OEMs building the next generation of green-energy technology.

Aluminium die casting is not just a manufacturing process it is a key enabler of the world’s transition to the growth of sustainable energy.