What Is Aluminium Die Casting? A Complete Beginner‑Friendly Guide

What Is Aluminium Die Casting? A Complete Beginner-Friendly

Introduction

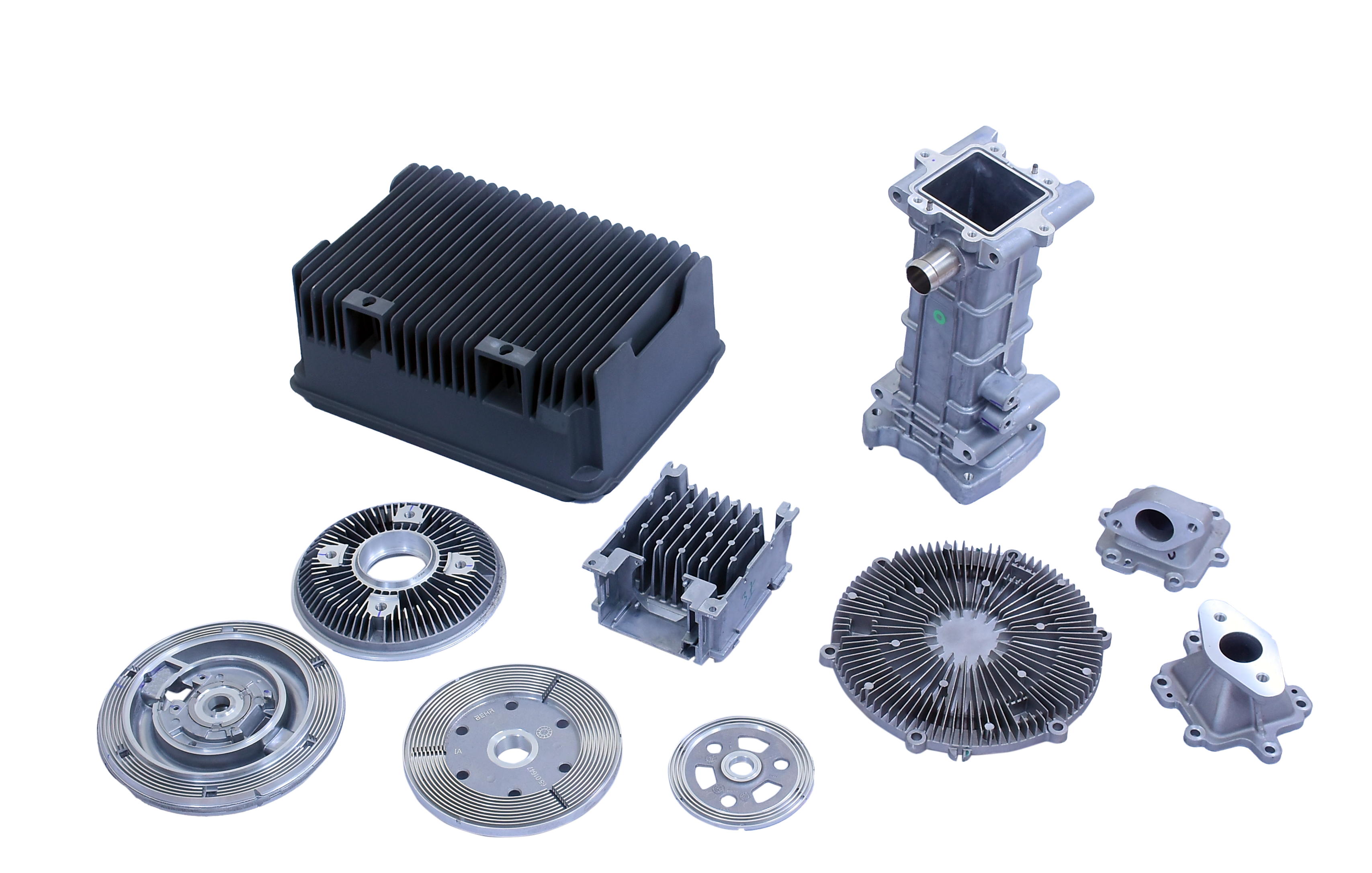

Aluminium die casting is a high-pressure manufacturing process used to produce precision aluminium components with excellent strength, accuracy, thermal performance, and durability. It is one of the most widely used processes in the automotive industry, electronics, renewable energy, and industrial machinery, due to its ability to create lightweight, complex shapes at scale.

This guide explains the die casting process, aluminium alloys, tooling design, advantages, common defects, and real-world applications using the same terminology people search for online.

What Is Aluminium Die Casting? (In Detail)

Aluminium die casting is a process where molten aluminium alloy is injected into a steel die (mold) under extremely high pressure typically 400–1500 bar.

It is considered one of the best technologies for producing:

- Die cast aluminium components

- Automotive die casting parts

- Heat sinks and electronic enclosures

- Precision aluminium housings

- High-volume industrial components

Because aluminium is lightweight, corrosion‑resistant, and thermally conductive, aluminium die casting is replacing heavier materials like steel and iron across many industries.

Step-by-Step: How Aluminium Die Casting Works

1. Die (Mold) Design and Preparation

High-pressure die casting requires a specially designed steel die built to withstand millions of cycles. The die includes:

- Cavities & cores for forming complex shapes

- Runner and gate system for smooth metal flow

- Cooling channels for temperature control

- Ejector pins to remove the part

Proper die casting mold design ensures:

- Lower porosity

- Better surface finish

- Faster cycle time

- Higher productivity

2. Melting the Aluminium Alloy

Popular alloys include:

- A380 aluminium alloy best all-round properties

- ADC12 excellent castability and low shrinkage

- A360 superior corrosion resistance & pressure tightness

- A356/A357 high strength after heat treatment

These alloys are melted at ~660°C and transferred to a cold-chamber die casting machine, the preferred system for aluminium.

3. High-Pressure Injection

This is the core of the high-pressure die casting process.

The molten aluminium is injected at high velocity and high pressure, ensuring:

- Complete cavity filling

- Thin wall sections (down to 1 mm)

- Dimensional accuracy

- High mechanical strength

4. Cooling & Solidification

The aluminium cools rapidly inside the die. Controlled cooling reduces defects such as:

- Porosity in die casting

- Shrinkage

- Warpage

5. Ejection and Trimming

Once solidified, the component is ejected and trimmed to remove:

- Gates

- Runners

- Overflows

The final part is ready for finishing, machining, or assembly.

Advantages of Aluminium Die Casting

- Lightweight but strong ideal for automotive and EV components

- High dimensional accuracy tight tolerances achievable

- Supports complex, thin-wall designs

- Excellent corrosion resistance

- Superior thermal & electrical conductivity

- Fast cycle time and scalable production

- Highly cost-effective for mass manufacturing

- Eco-friendly & recyclable material

These benefits make aluminium die casting the preferred choice for precision components compared to gravity casting, sand casting, or CNC machining in high volumes.

Limitations

- High initial tooling cost

- Susceptible to porosity if not controlled

- Not ideal for very large parts

- Requires uniform wall thickness

Aluminium Die Casting Defects & Solutions

Common issues include:

- Gas porosity controlled by vacuum die casting or slow fill time

- Cold shuts solved with better gating design

- Shrinkage porosity improved with optimized die temperature

- Flash managed with precise clamping force

These are standard search terms for engineers seeking solutions.

Applications of Aluminium Die Casting

1. Automotive Industry (High search volume)

- Gearbox housings

- EV motor casings

- Brackets and mounts

- Engine covers

- Heat sinks

2. Electronics & Electricals

- EMI/EMC shielding enclosures

- LED lighting housings

- Heat-dissipating components

3. Renewable Energy Equipment

- Solar inverter housings

- EV charging station casings

- Wind turbine control components

- Battery energy storage system parts

4. Industrial Machinery

- Pump and compressor housings

- Pneumatic tool frames

- Robotics components

Why Manufacturers Prefer Aluminium Die Casting

Manufacturers often search for phrases like “best aluminium die casting manufacturer India”, “custom aluminium die casting services”, and “precision die casting company.”

Customers prefer aluminium die casting because it provides:

- Better durability than plastics

- Faster production than machining

- Stronger and more accurate parts than sand casting

- Lower cost per part in large batches

Types of Die Casting Processes

Aluminium components are manufactured using three primary die casting methods. Each offers unique benefits based on complexity, volume, strength, and application.

1. Gravity Die Casting (GDC)

Short form: GDC

Long form: Gravity Die Casting

How it works: Molten aluminium is poured into a permanent steel mold using gravity only, without external pressure.

Best for:

- Medium-volume production

- Thick-walled parts

- Strong, structurally reliable components

Advantages:

- Low porosity

- Good mechanical properties

- Suitable for heat treatment

2. Low Pressure Die Casting (LPDC)

Short form: LPDC

Long form: Low Pressure Die Casting

How it works: Molten aluminium is pushed upward into the die under low pressure (0.7–1.5 bar).

Best for:

- Automotive wheels (alloy wheels)

- High-strength structural parts

- Pressure-tight components

Advantages:

- Very clean metal flow

- Excellent surface finish

- Better control → reduced defects

3. High Pressure Die Casting (HPDC)

Short form: HPDC

Long form: High Pressure Die Casting

How it works: Molten aluminium is injected into the die at high pressure (400–1500 bar).

Best for:

- Thin-walled parts

- High-volume production

- Complex geometric components

- Automotive, electronics, renewable energy housings

Advantages:

- Fastest production method

- Highest accuracy and detail

- Very economical for mass manufacturing

Summary

Aluminium die casting is a high-precision, scalable, and cost-effective manufacturing process used across multiple industries. Its ability to create lightweight, complex, high-strength components makes it a leading technology in the future of manufacturing.